Link Electric Stamping Press Controls and Safety Equipment

DMS sells, services, and supports LINK Electric Stamping Press Controls and Safety Devices for the metal stamping and fabrication industry. In fact, this is what our business was founded on and how we’ve developed a trusted reputation in this industry. DMS is proudly partnered with LINK Press Controls who’s product line is flexible enough to provide a specific control or monitoring function or to provide integrated systems for your presses.

About LINK

Link Systems develops and manufactures press automation controls, tonnage monitoring, die protection, programmable limit switch and presence sensing devices for the metal forming industry. Manufactured and assembled completely in Nashville, TN USA, Link is committed to providing practical solutions and needs for automation, productivity, quality, safety, and shop floor information storage and retrieval.

For an overview of the electronic controls, monitors and safety devices we can provide you with, just click on any of the tabs below that contains detailed information on our products. If you are not sure exactly what your equipment needs or would like to speak to one of our experts, simply call us @ 214-307-2411 or fill out the form below and we will get back to you as soon as possible.

Press & Automation Controls

Safety Light Curtains

PLS & Die Protection

Tonnage Monitoring

Press & Automation Controls

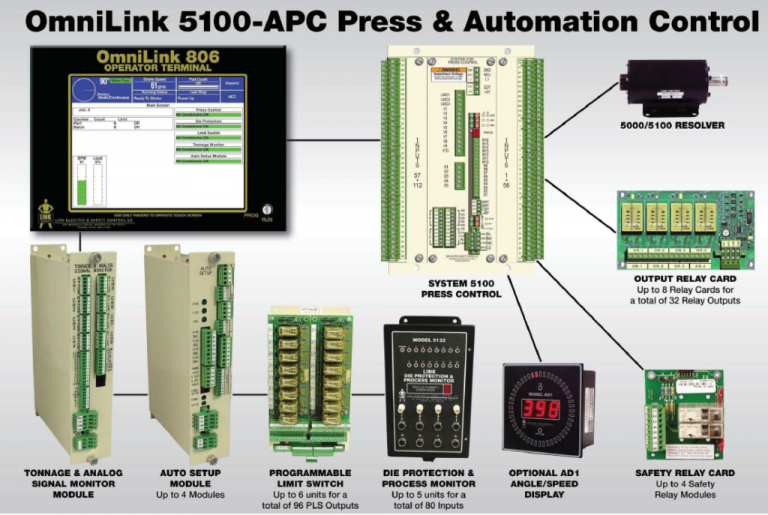

5100-APC Press Control

Gain ultimate press and automation control using the OmniLink 806 operator terminal to integrate the 5100 Press Control with functional modules to increase safety, productivity, and quality in your mechanical press production systems.

5100-MPC Press Control

Maximize press safety and productivity with a cost-effective, mechanical power press control with moderate automation capability.

5100-AMC Press Automation Control

Provides complete automation control, monitoring, sequencing, and communications for part revolution mechanical power presses.

5100-AMC-Servo

Provides complete automation control, monitoring, sequencing, and communications for part revolution mechanical power presses.

Safety Light Curtains

Link Black Max Safety Light Curtains

Since designing and manufacturing one of the first safety light curtain devices in the early 1970s, our team has engineered and delivered thousands of press productivity and safety solutions to the metalforming industry. Today, our Black Max Safety Light Curtains are purpose-built to integrate with your press production system, meet OSHA, ANSI, and other safety standards, and prevent costly accidents while protecting personnel from point-of-operation hazards.

PLS & Die Protection

2600 PLS & Die Protection

Just one die crash can be financially devastating to your bottom line. With the System 2600, you can monitor process sensors and additionally sequence automation with programmable limit switches.

Tonnage Monitoring

The 1200 Tonnage Monitor

The System 1200 measures and displays the forces being applied to the frame of a press during the working portion of the stroke. These forces are compared with allowable limits based on the capacity of the machine and correct operation of the die and material being used.

5100-APC Press Control

Gain ultimate press and automation control using the OmniLink 806 operator terminal to integrate the 5100 Press Control with functional modules to increase safety, productivity, and quality in your mechanical press production systems.

5100-MPC Press Control

Maximize press safety and productivity with a cost-effective, mechanical power press control with moderate automation capability.

5100-AMC Press Automation Control

Provides complete automation control, monitoring, sequencing, and communications for part revolution mechanical power presses.

5100-AMC-Servo

Provides complete automation control, monitoring, sequencing, and communications for part revolution mechanical power presses.

Link Black Max Safety Light Curtains

Since designing and manufacturing one of the first safety light curtain devices in the early 1970s, our team has engineered and delivered thousands of press productivity and safety solutions to the metalforming industry. Today, our Black Max Safety Light Curtains are purpose-built to integrate with your press production system, meet OSHA, ANSI, and other safety standards, and prevent costly accidents while protecting personnel from point-of-operation hazards.

2600 PLS & Die Protection

Just one die crash can be financially devastating to your bottom line. With the System 2600, you can monitor process sensors and additionally sequence automation with programmable limit switches.

The 1200 Tonnage Monitor

The System 1200 measures and displays the forces being applied to the frame of a press during the working portion of the stroke. These forces are compared with allowable limits based on the capacity of the machine and correct operation of the die and material being used.

Need more help?

Our knowledgeable team is standing by to help you find solutions.